Air Operated Diaphragm Pumps (AOD pumps) have revolutionized fluid handling across industries with their robust design and versatile applications. These pumps utilize compressed air as a power source, making them suitable for diverse operational environments where electrical power may be limited or hazardous. Their ability to handle a wide range of fluids, including corrosive and abrasive substances, highlights their reliability and efficiency in various industrial processes. This article explores the significant role of AOD pumps in enhancing fluid handling efficiency, examining their operational mechanisms, advantages, applications across industries, maintenance strategies, and future technological advancements.

Introduction To Air Operated Diaphragm Pumps

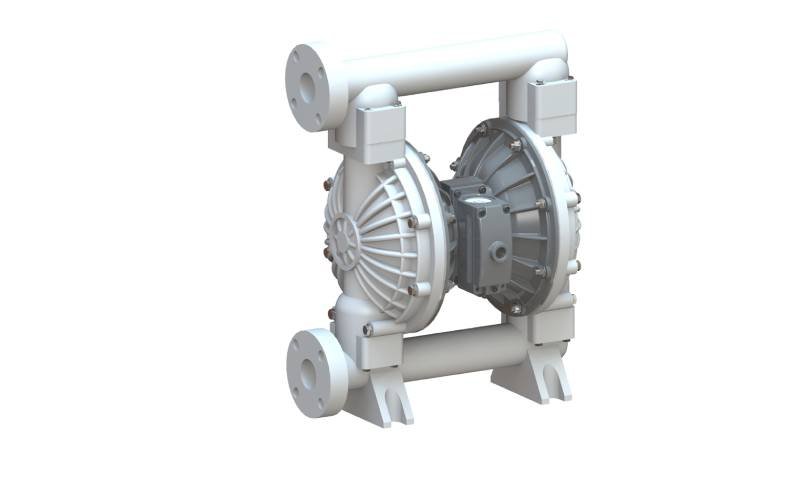

Air Operated Diaphragm Pumps are positive displacement pumps that utilize compressed air to operate. They are characterized by their simple yet effective design, consisting of two diaphragms that reciprocate back and forth to create suction and discharge cycles. Typically constructed from materials such as plastic, metal alloys, or elastomers, these pumps can withstand aggressive fluids and harsh operating conditions. AOD pumps are widely used in industries where reliability, versatility, and safety are paramount, including chemical processing, mining, wastewater treatment, and food and beverage production.

Key Advantages Of Air Operated Diaphragm Pumps

The key advantages of Air Operated Diaphragm Pumps (AOD pumps) lie in their robustness, versatility, and operational flexibility. Unlike traditional pumps, AOD pumps can run dry without damage, handle viscous fluids, and operate with variable flow rates and pressures. Their ability to self-prime and run quietly makes them suitable for applications where noise reduction is essential. Moreover, AOD pumps offer excellent suction lift capabilities, enabling them to handle fluids containing solids or particles up to a certain size without clogging. These features make AOD pumps ideal for transferring fluids across a wide range of viscosities and compositions in industrial settings.

Operational Mechanism Of Air Operated Diaphragm Pumps

The operational mechanism of Air Operated Diaphragm Pumps (AOD pumps) centers on the reciprocating action of two flexible diaphragms. When compressed air is introduced into one chamber, it flexes one diaphragm inward, creating a vacuum and drawing fluid into the pump chamber. Simultaneously, the other diaphragm moves outward, expelling the fluid from the opposite chamber. This alternating cycle of suction and discharge is efficient and reliable, ensuring consistent fluid flow with minimal pulsation. The valve-less and seal-less design of AOD pumps simplifies maintenance and reduces downtime, contributing to overall operational efficiency.

Applications Of Air Operated Diaphragm Pumps In Various Industries

Air Operated Diaphragm Pumps (AOD pumps) find extensive applications across diverse industries due to their ability to handle challenging fluids and environments. In chemical processing, they transfer corrosive chemicals safely and efficiently. In mining operations, AOD pumps are used for dewatering and slurry transfer, where solids handling capabilities are crucial. Municipalities rely on these pumps for wastewater treatment, where they manage sewage and sludge with ease. Additionally, AOD pumps are integral to food and beverage production, handling ingredients and by-products without contamination. Their versatility extends to oil and gas, pharmaceuticals, and automotive sectors, showcasing their adaptability in various industrial processes.

Maintenance And Optimization Of Air Operated Diaphragm Pumps

Maintenance of Air Operated Diaphragm Pumps (AOD pumps) is relatively straightforward due to their simple design and durable construction. Regular inspections of diaphragms, valves, and seals ensure proper functioning and prevent unexpected failures. Manufacturers often provide maintenance guidelines specific to their pumps, detailing inspection intervals and recommended replacement schedules for wear parts. Optimizing AOD pump performance involves monitoring air and fluid pressures, adjusting flow rates as needed, and ensuring proper filtration to extend component life. By adhering to proactive maintenance practices, industries can maximize uptime and reduce operating costs associated with pump maintenance.

Environmental And Economic Benefits Of Air Operated Diaphragm Pumps

Air Operated Diaphragm Pumps (AOD pumps) offer significant environmental and economic benefits compared to traditional pump technologies. Their energy efficiency, especially in applications where electricity costs are high, reduces operational expenses and carbon footprints. AOD pumps contribute to environmental sustainability by minimizing leaks and emissions, particularly crucial in handling volatile or hazardous fluids. Their durable construction and longevity translate into lower lifecycle costs, making them a cost-effective investment for industries seeking reliable fluid handling solutions. Additionally, the ability of AOD pumps to handle diverse fluids reduces the need for multiple pump types, further optimizing resource utilization and reducing waste.

Future Trends In Air Operated Diaphragm Pump Technology

The future of Air Operated Diaphragm Pump (AOD pump) technology is marked by advancements aimed at enhancing efficiency, reliability, and integration with digital monitoring and control systems. Innovations in materials and manufacturing processes will continue to improve pump performance and longevity, expanding their application range in specialized industries. Integration of smart sensors and IoT (Internet of Things) capabilities will enable real-time monitoring of pump health and performance metrics, facilitating predictive maintenance and optimizing operational efficiency. Furthermore advancements in pump automation and remote control capabilities will empower industries to streamline operations and enhance overall productivity.

Conclusion

In conclusion, Air Operated Diaphragm Pumps (AOD pumps) play a crucial role in improving fluid handling efficiency across various industries. Their robust design, operational versatility, and ability to handle challenging fluids make them indispensable in applications ranging from chemical processing to wastewater treatment. By understanding the operational mechanisms, advantages, applications, maintenance strategies, and future trends of AOD pumps, industries can leverage these technologies to enhance productivity, reduce operational costs, and achieve sustainable fluid handling practices. As technological advancements continue to evolve, AOD pumps will remain at the forefront of innovation, meeting the dynamic needs of modern industrial processes.