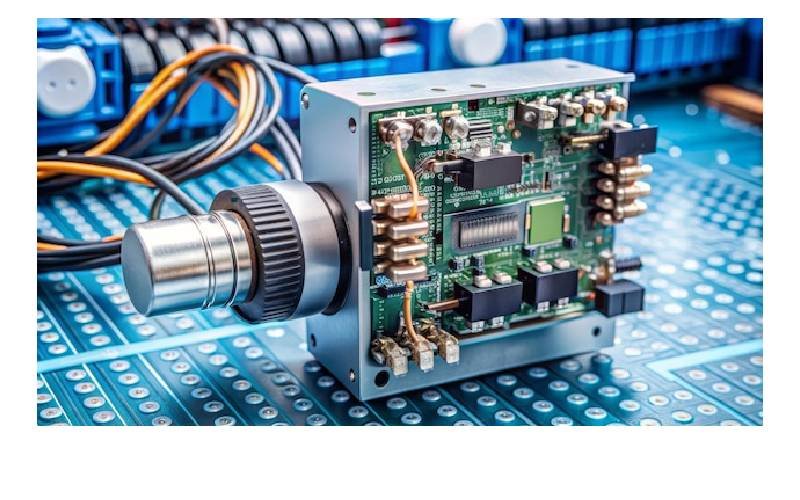

Ensuring reliability and safety in electro-mechanical assembly is crucial for the successful operation of various systems that integrate electrical and mechanical components. This process is fundamental to a wide range of applications, from consumer electronics to industrial machinery and aerospace systems. Electro mechanical assemblies combine electrical circuits with mechanical structures, demanding a meticulous approach to ensure that each component functions correctly and harmoniously within the system. Reliability in this context means that the assembly performs its intended function consistently over time, while safety involves protecting both the end-user and the system from potential hazards. As technology advances and systems become increasingly complex, maintaining high standards of reliability and safety becomes more challenging and essential. This requires a comprehensive understanding of best practices, quality control measures, advanced testing techniques, design considerations, component selection, risk mitigation, and adherence to safety protocols. Addressing these factors effectively ensures that electro-mechanical assemblies operate reliably and safely, reducing the risk of failures and enhancing overall system performance.

Ensuring Reliability In Electro Mechanical Assembly Processes

To ensure reliability in electro mechanical assembly processes, adhering to best practices is essential. These practices encompass various aspects of assembly, from initial design to final testing. One of the key best practices is the implementation of thorough design reviews. These reviews help identify potential issues early in the development process, allowing for adjustments before assembly begins. Additionally, using standardized assembly procedures and documentation ensures consistency and reduces the likelihood of errors. Proper training for assembly personnel is also critical, as it ensures that they are knowledgeable about the specific requirements and standards of the assembly process. Regular maintenance and calibration of assembly equipment further contribute to reliability by ensuring that tools and machines operate within their specified parameters. Another important practice is to incorporate redundancy in critical systems, which provides backup functionality in case of component failure. Finally, continuous monitoring and feedback loops during the assembly process help in identifying and addressing any issues promptly. By following these best practices, manufacturers can enhance the reliability of electro-mechanical assemblies, ensuring that they perform as expected over their operational lifespan.

Quality Control Measures Enhance Safety In Electro Mechanical Assembly

Quality control measures play a vital role in enhancing safety in electro-mechanical assembly by systematically identifying and addressing potential issues that could lead to failures or hazards. These measures include rigorous inspection processes, testing protocols, and adherence to industry standards. One of the primary quality control techniques is the use of detailed inspection checklists that cover every aspect of the assembly, from component placement to soldering and wiring. Visual inspections, along with automated inspection tools, help detect defects such as misalignments, soldering errors, or damaged components. Additionally, functional testing ensures that the assembly operates correctly under various conditions and load scenarios. Implementing reliability testing, such as accelerated life testing, simulates extended operational conditions to identify potential failure points before the assembly is deployed. Furthermore, adherence to safety standards and regulations, such as those set by organizations like UL or ISO, ensures that the assembly meets established safety requirements. By integrating these quality control measures into the electro-mechanical assembly process, manufacturers can significantly reduce the risk of safety issues, enhance the reliability of the final product, and ensure compliance with safety regulations.

Advanced Testing Techniques In Validating Electro Mechanical Assembly Reliability

Advanced testing techniques play a crucial role in validating the reliability of electro-mechanical assemblies by providing detailed insights into their performance and identifying potential issues before they impact end-users. These techniques go beyond traditional testing methods, offering a more comprehensive evaluation of the assembly’s functionality, durability, and safety. One key technique is accelerated life testing, which subjects the assembly to extreme conditions to simulate long-term usage and identify weaknesses. Another important method is thermal cycling testing, which assesses how the assembly performs under fluctuating temperatures, revealing any issues related to thermal expansion or contraction. Additionally, electromagnetic compatibility (EMC) testing ensures that the assembly does not interfere with or is not affected by external electromagnetic fields, which is crucial for maintaining system performance and safety. Reliability testing often includes vibration and shock tests to simulate the physical stresses that the assembly may encounter during operation. By employing these advanced testing techniques, manufacturers can validate the reliability of electro-mechanical assemblies, ensuring that they meet performance standards and can withstand real-world conditions.

Improving Safety And Reliability In Electro Mechanical Assembly

Design considerations are fundamental for improving both safety and reliability in electro-mechanical assembly. An effective design not only ensures that components function together seamlessly but also incorporates features that mitigate potential risks and enhance overall performance. One crucial design consideration is the selection of materials that can withstand the operational environment, such as high temperatures, moisture, or corrosive substances. Designing for ease of assembly and maintenance also contributes to reliability, as it simplifies the process and reduces the likelihood of errors during assembly. Additionally, incorporating safety features such as fail-safes and alarms can help prevent accidents and system failures. For example, redundant circuits or backup systems can ensure that the assembly continues to function even if a primary component fails. Another important aspect is the use of design guidelines and standards, which provide a framework for creating reliable and safe assemblies. By following these design considerations, manufacturers can improve the safety and reliability of electro-mechanical assemblies, resulting in higher quality products and reduced risk of failures.

Component Selection On The Reliability Of Electro Mechanical Assembly

Component selection has a significant impact on the reliability of electro-mechanical assembly, as the quality and compatibility of components directly influence the overall performance and durability of the system. Choosing high-quality components that meet industry standards and specifications is essential for ensuring reliable operation. For electrical components, factors such as voltage ratings, current capacities, and thermal characteristics must be considered to ensure that they can handle the demands of the assembly. For mechanical components, considerations include material strength, tolerance levels, and wear resistance. Additionally, selecting components from reputable suppliers with a track record of reliability helps reduce the risk of defects and failures. Compatibility between electrical and mechanical components is another critical factor, as mismatches can lead to performance issues or damage. By carefully selecting components based on their quality, compatibility, and performance characteristics, manufacturers can enhance the reliability of electro-mechanical assemblies and ensure that they operate effectively under various conditions.

Common Challenges And Solutions In Electro Mechanical Assembly For Safety

Mitigating risks in electro-mechanical assembly involves addressing common challenges that can impact safety and reliability. One challenge is managing the complexity of modern assemblies, which often involves integrating numerous components with varying requirements. To address this challenge, manufacturers can use modular designs that simplify the assembly process and allow for easier troubleshooting and maintenance. Another challenge is ensuring proper thermal management, as excessive heat can lead to component failures or safety hazards. Solutions include incorporating heat sinks, cooling systems, and thermal insulation to dissipate heat and protect sensitive components. Electromagnetic interference (EMI) is another common issue that can affect assembly performance and safety. Shielding techniques and filtering components can help mitigate EMI and ensure reliable operation. Additionally, managing the risk of human error during assembly is crucial. Implementing standardized procedures, providing thorough training, and using automated assembly tools can reduce the likelihood of errors. By addressing these challenges and implementing effective solutions, manufacturers can enhance the safety and reliability of electro-mechanical assemblies.

Safety Protocols And Standards Into Electro Mechanical Assembly To Prevent Failures

Integrating safety protocols and standards into electro-mechanical assembly is essential for preventing failures and ensuring that assemblies meet safety and reliability requirements. Adhering to established standards, such as those from the International Electrotechnical Commission (IEC) or the American National Standards Institute (ANSI), provides a framework for designing and manufacturing safe and reliable assemblies. These standards cover various aspects of electro-mechanical assembly, including component specifications, testing procedures, and safety measures. Implementing safety protocols involves establishing procedures for identifying and mitigating potential risks during the assembly process. This includes conducting risk assessments, implementing safety checks, and ensuring compliance with safety regulations. Regular audits and inspections also play a role in maintaining safety standards and identifying areas for improvement. By integrating these safety protocols and standards into the assembly process, manufacturers can prevent failures, enhance the reliability of electro-mechanical assemblies, and ensure that products meet safety and performance expectations.

Conclusion

Ensuring reliability and safety in electro-mechanical assembly is a multifaceted endeavor that requires attention to detail at every stage of the process. From adhering to best practices and implementing quality control measures to employing advanced testing techniques and addressing design considerations, each aspect plays a crucial role in achieving high standards of performance and safety. Component selection, risk mitigation, and adherence to safety protocols further contribute to the overall reliability and safety of electro-mechanical assemblies. As technology continues to advance and systems become more complex, the importance of these considerations will only grow. By focusing on these areas, manufacturers can develop robust and dependable electro-mechanical assemblies that meet the demanding requirements of modern applications and ensure safe, reliable operation.